When purchasing a quality pair of gloves, the

first factor considered is construction or

"cut." The two most common types are

Clute and Gunn. Clute cut provides comfort with

no seams in the palm. Gunn cut is primarily used

in leather gloves to protect the seams from wear.

When purchasing a quality pair of gloves, the

first factor considered is construction or

"cut." The two most common types are

Clute and Gunn. Clute cut provides comfort with

no seams in the palm. Gunn cut is primarily used

in leather gloves to protect the seams from wear.

There are a variety of cuff styles to choose

from. Most cotton and jersey work gloves have a

snug knit wrist while leather gloves have a

slip-on or shirred style cuff. Leather palm

styles have safety or gauntlet cuffs or knit

wrists.

There are a variety of cuff styles to choose

from. Most cotton and jersey work gloves have a

snug knit wrist while leather gloves have a

slip-on or shirred style cuff. Leather palm

styles have safety or gauntlet cuffs or knit

wrists.

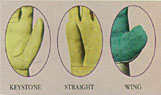

We have three types of thumbs; extra comfortable

one-piece keystone, one-piece straight thumb with

no seam on the outer side, and wing thumb, with

no seams on wearing surface.

We have three types of thumbs; extra comfortable

one-piece keystone, one-piece straight thumb with

no seam on the outer side, and wing thumb, with

no seams on wearing surface.

Our cotton gloves are economical, lightweight,

but strong. The fabric is tightly woven to assure

greater seam strength. Our jerseys are warm for

year-round use. We use a full size die for

comfortable, roomy gloves. Our flannel chore

gloves are strong and moisture resistant because

two layers of material are bonded by rubber based

adhesive to produce the best chore glove on the

market. Our PVC coated gloves are waterproof and

tough, yet flexible....and we combine leather and

cotton for our leather palm gloves.

Our cotton gloves are economical, lightweight,

but strong. The fabric is tightly woven to assure

greater seam strength. Our jerseys are warm for

year-round use. We use a full size die for

comfortable, roomy gloves. Our flannel chore

gloves are strong and moisture resistant because

two layers of material are bonded by rubber based

adhesive to produce the best chore glove on the

market. Our PVC coated gloves are waterproof and

tough, yet flexible....and we combine leather and

cotton for our leather palm gloves.

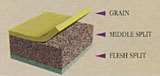

Leather hides removed from the animal are too

thick for commercial uses so they must first be

cut into layers. Generally, a hide is divided

into three layers.

Leather hides removed from the animal are too

thick for commercial uses so they must first be

cut into layers. Generally, a hide is divided

into three layers.

The smooth outer layer, or grain side, is used for better gloves where "look" and dexterity are important. The bottom layer, the flesh split or suede, is used mostly in leather palm styles, most of which have linings to protect the hands against its roughness. We don't use the middle split because it has no tensile strength.

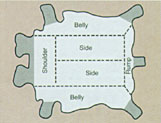

A-Grade leather comes from the side and belly areas, while B-Grade leather comes from the shoulder and rump areas. Wells Lamont gets 11 pairs of A-Grade and 5 pairs of B-Grade gloves out of each cowhide, while a typical pigskin yields 5 A-Grade and 2 B-Grade pairs.

Capeskin

soft and supple grain sheepskin leather is used in tasks where optimum dexterity and sensitivity are needed.

Cowhide

is most commonly used in our leather gloves. Supple, yet strong belly leather is our volume leader. Side split and shoulder split leather are best for leather palm gloves.

Deerskin

leather, naturally soft and supple, is also warm and long wearing. We use the finest quality deerskin in the industry for our work gloves.

Goatskin

leather has the highest natural lanolin content available, making it soft and pliable, while actually improving its durability. For medium duty jobs.

Pigskin

leather is tanned for toughness and pliability. Soft drying and flexible, even after repeated wettings, its tough on the job, but easy on the hands.

BBT=Breakthrough Time * ID=Insufficient Data * NR=Not Recommended