Establishing An Effective

Respirator ProgramThe respirator

program outlined below is based on the

requirements established in Section 1910.134(b)

of the Occupational Safety and Health Standards

(found in Title 29 of the Code of Federal

Regulations) for an 11-point minimal acceptable

respirator program:

- Establish Written Operating Procedures

You must develop a formal written

document outlining every aspect of your

respirator program. Some of the details

which must be included are:

- How contaminants are controlled.

- How contaminant concentrations

are measured.

- How respirators are selected,

used, cleaned, inspected,

repaired and stored.

- Respirator Selection

Proper selection of respirators shall be

made according to the guidance of ANSI

Z88.2-1992. In choosing respirators,

consider the nature and extent of the

hazard, the work requirements and

conditions, and the characteristics and

limitations of the respirators available.

When you examine the hazardous

environment, some of the questions you

should ask are:

- What are the contaminants?

- What are their concentrations?

- Are they gaseous or particulate?

- Do they have adequate warning

properties?

- Are they immediately dangerous to

life or health?

- Does the air contain at least

19.5% oxygen?

- Are protective clothing and hand

protection necessary?

- Train Respirator Users

Every respirator wearer must receive

fitting instructions, including

demonstrations and practice in how to

determine if it fits properly.Keep in

mind that respirators cannot be used if

anything interferes with the seal of the

facepiece to an individual's face. That

includes sideburns, beards, temple pieces

of eye glasses, severe scars and

wrinkles, and even missing dentures.

- Assign Individual Respirators Where

Practicable

When respirators are assigned

individually, there is less chance that a

worker will use one that doesn't give him

or her the best protection. And sometimes

it overcomes the unwillingness of an

employee to wear a respirator if he or

she thinks someone else has used it, and

that it wasn't properly sanitized

afterward.

- Regularly Clean and Sanitize

Respirators

There is a three-step method of washing

the respirator in a detergent or

cleaner-sanitizer, rinsing it in warm

water, and air drying it that is outlined

in ANSI Z88.2-1992.

- Respirator Storage

Storing respirators in clean bags or

other suitable containers in a clean and

sanitary location maintains the integrity

of your cleaning and maintenance program.

- Respirator Inspection and Maintenance

Inspection and maintenance of respirators

in accordance with the manufacturer's

instructions will ensure that the

respirators, when properly used, will

give the wearer the best possible

protection.

- Monitor the Work Area

Make sure the right respirator is being

used.

- Continually Enforce and Evaluate the

Respirator Program

Frequent, random inspections shall be

conducted by a qualified individual to

assure that respirators are properly

selected, used, cleaned, and maintained.

- Medical Evaluation of Respirator

Wearers

If a potential respirator wearer is not

physically able to perform the work using

a respirator, the use of a respirator may

create more problems than it solves.

- Use Approved or Accepted Respirators

The respirators you use in your work

environment must be NIOSH/MSHA certified,

where applicable, or be otherwise

accepted to provide adequate protection

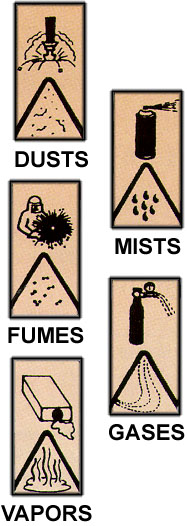

for the hazards encountered. DUSTS

are created when solid material breaks

down and gives off fine particles that

float in the air before settling by

gravity. Dusts are produced by operations

such as grinding, crushing, drilling,

blasting, sanding, and milling.

DUSTS

are created when solid material breaks

down and gives off fine particles that

float in the air before settling by

gravity. Dusts are produced by operations

such as grinding, crushing, drilling,

blasting, sanding, and milling.

MISTS are particles formed from

liquid materials by atomization and

condensation processes. For example,

mists can be created by spraying

operations, plating operations, and

mixing and cleaning operations.

FUMES are created when solid

materials vaporize under high heat. The

metal vapor cools and condenses into an

extremely small particle, with a particle

size generally less than one micrometer

in diameter. Fumes can come from

operations such as welding, smelting, and

pouring of molten metal.

VAPORS are the gaseous state of

substances that are either liquids or

solids at room temperature. They are

formed when solids or liquids evaporate.

Gasoline is an example of a liquid that

evaporates easily, producing gasoline

vapors. Other examples are paint thinners

and degreaser solvents.

Personal

Protective Equipment Levels

Level A

Protection should be used when:

- The hazardous substance has

been identified and requires the highest

level of protection for skin, eyes, and

the respiratory system based on either

the measured (or potential for) high

concentration of atmospheric vapors,

gases, or particulates; or the site

operations and work functions involve a

high potential for splash, immersion, or

exposure to unexpected gases, vapors, or

particulates of materials that are

harmful to the skin or capable of being

absorbed through the skin;

- Substances with a high

degree of hazard to the skin are known or

suspected to be present, and skin contact

is possible; or

- Operations are being

conducted in confined, poorly ventilated

areas, and the absence of conditions

requiring Level A have not yet been

determined.

I. Level A - to be

selected when the greatest level of respiratory

protection is required: Positive pressure, full

facepiece self-contained breathing apparatus

(SCBA), or positive pressure supplied air

respirator with escape SCBA, approved by the

National Institute for Occupational Safety and

Health (NIOSH).

Note: In 29CFR 1910.120 (g) (3)

(iii), OSHA requires that Level A respiratory

protection be used "when chemical exposure

levels present will create a substantial

possibility of immediate death, immediate serious

illness or injury, or impair the ability to

escape."

Level B

Level B protection should be used when:

- The type and atmospheric

concentration of substances have been

identified and require a high level of

respirator protection, but less skin

protection;

- 2. The atmosphere contains

less than 19.5 percent oxygen; or

- The presence of

incompletely identified vapors or gases

is indicated by a direct-reading organic

vapor detection instrument, but vapors

and gases are not suspected of containing

high levels of chemicals harmful to skin

or capable of being absorbed through the

skin.

II. Level B - to be

selected when the highest level of respiratory

protection is necessary, but a lesser level of

skin protection is needed: Positive pressure,

full facepiece self-contained breathing apparatus

(SCBA), or positive pressure air respirator with

escape SCBA (NIOSH-approved).

Note: Level B respiratory

protection specified by OSHA is identical to

Level A respiratory protection. The hazards

involve "atmospheres that present severe

inhalation hazards and that do not represent a

severe skin hazard; or that do not meet the

criteria for use of air-purifying

respirators."

Level C

Level C protection should be used when:

- The atmospheric

contaminants, liquid splashes, or other

direct contact will not adversely affect

or be absorbed through any exposed skin;

- The types of air

contaminants have been identified,

concentrations measured, and an

air-purifying respirator is available

that can remove the contaminants; and

- All criteria for the use of

air-purifying respirators are met.

III. Level C - to be

selected when the concentration(s) and type(s) of

airborne substance(s) is known and the criteria

for using air-purifying respirators are met:

- Full-face or half-mask

air-purifying respirators

(NIOSH-approved);

- Escape mask (optional);

Note: In 29CFR 1910.120 (g) (3)

(iii) (vi) OSHA requires that respirators be

selected and used in accordance with 29CFR

1910.134. Respirators (NIOSH-approved) other than

those described in Levels A, B, C and D may be

more appropriate and may be used to provide the

proper level of protection. Thus, where Level A

or B respiratory protection is not required

(e.g., in a non-IDLH atmosphere), but

air-purifying respirators are inadequate because

of the presence of excessive concentration levels

of gases or vapors having poor warning

properties, suitable airline respirators may be

used.

Level D

Level D protection should be used when:

- The atmosphere contains no

known hazard;

- Work functions preclude

splashes, immersion, or the potential for

unexpected inhalation of or contact with

hazardous levels of any chemicals.

IV. Level D - no

respirator is required. However, OSHA does

specify an "escape mask" as optional

equipment to insure a safe escape should an

inhalation hazard unexpectedly and suddenly

appear.

New

Respiratory Standard - 42CFR84

NIOSH (National Institute

for Occupational Safety and Health) establishes

new testing and certification requirements for

particulate respirators and filters.

Reasons For Change

New Filter classifications

Three-year transition

period

![]()

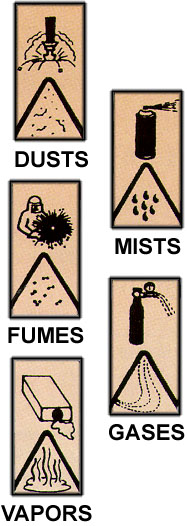

DUSTS

are created when solid material breaks

down and gives off fine particles that

float in the air before settling by

gravity. Dusts are produced by operations

such as grinding, crushing, drilling,

blasting, sanding, and milling.

DUSTS

are created when solid material breaks

down and gives off fine particles that

float in the air before settling by

gravity. Dusts are produced by operations

such as grinding, crushing, drilling,

blasting, sanding, and milling.